- We help companies move towards a circular industry by supporting them in developing test benches that can be used to test the performance of a component after remanufacturing or overhaul.

- Goal:

- More reuse of parts.

- More remanufacturing in Flanders.

- More ecological and economic benefits.

Contact

kris.martens@kdg.be

+32 474 91 79 05

- Duration research project: 01 May 2023 - 31 April 2024

-

Finance: IOF POC

-

Research centre: Sustainable Industries

Problem definition

Passenger cars, commercial vehicles and other industrial applications today consist of several mechatronic components that work together as one unit. Purely mechanical parts have evolved into mechatronic components that must communicate with each other via internal communication networks to exchange sensor information, operating states, commands, and other application-specific data. This necessary communication and the increasing complexity of the parts leads to (increasing) problems when testing these components after remanufacturing.

Problems in the traditional remanufacturing process

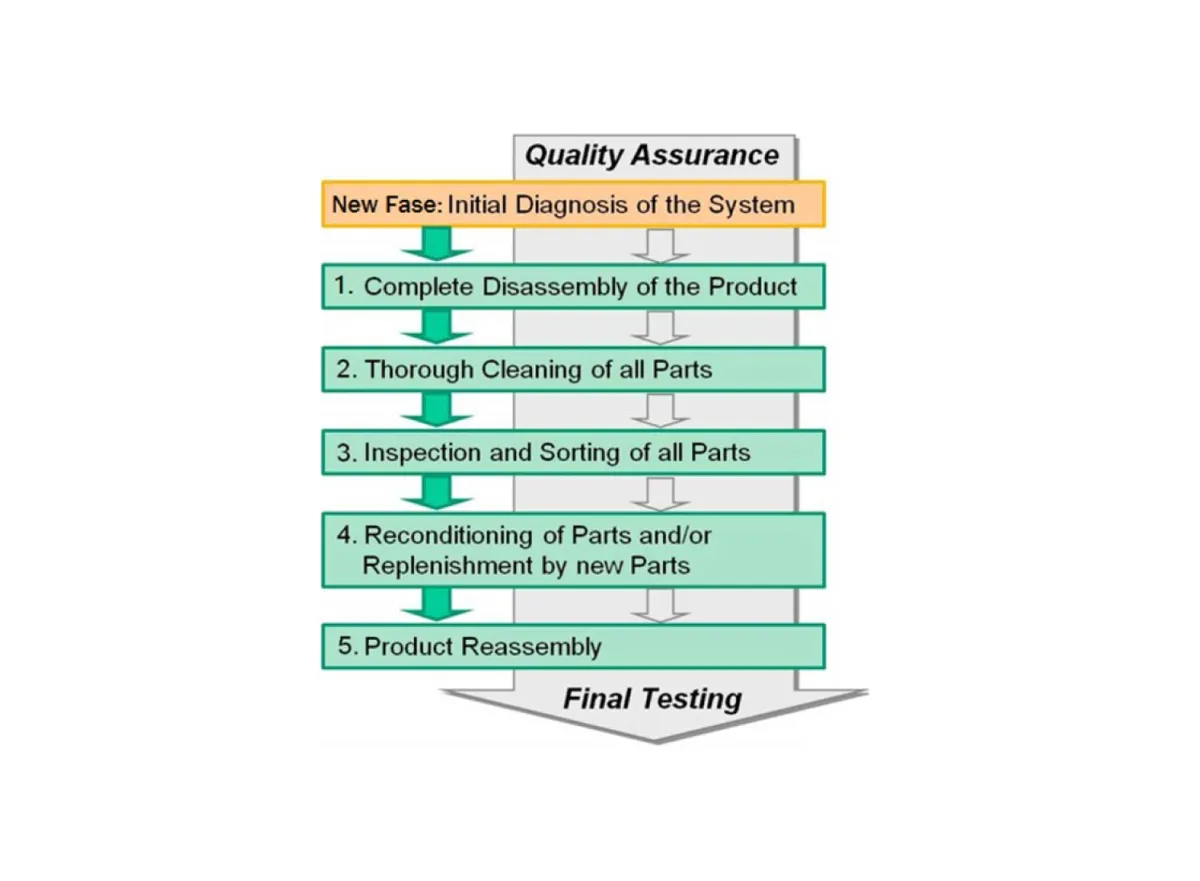

To provide quality assurance to the customer, the existing remanufacturing process, which consists of 5 standard steps (Figure 1), is completed by a final test phase. In this final test phase, the investment, fear of complexity, and lack of knowledge about the network systems cause problems in the traditional remanufacturing process. For many companies, it therefore becomes impossible to perform this quality control of the remanufactured part. In order to make this quality control possible, a first additional step must be added to the process. This step consists of analyzing the inputs, outputs, and network communications, which together should result in an input/output and network simulation that allows the remanufactured part to be tested again on the bench. This complexity and the associated problems are slowing down the growth or development of new activities in this sector, which is made up of companies that are already active or want to become active in the field of automotive remanufacturing.

Universal method and hardware tool

In a previous project, U-CANsim, we looked for a targeted approach to tackle these issues. Our researchers were able to bring the mechatronic component in testing into a functional state by simulating the network communication and required analog/digital inputs to validate the successful remanufacturing. A fully functional demo case has been developed that allows the testing of a common rail engine management system (engine ECU) independently of the vehicle.

This CremAN project explores the form in which this accumulated expertise can be developed into a universal method and hardware tool that can be widely used in the remanufacturing of mechatronic components. We are primarily looking at the needs of the industry and the level and/or form of support desired. This could range from offering a simulation file and assistance in purchasing the necessary hardware and software, to offering complete test benches with optional service and update contracts for new parts to be remanufactured.

Researchers

Want to know more, collaborate or have a press question?

You can collaborate with our research centre Sustainable Industries on topics such as:

- Greening chemical processes and reusing waste streams.

- AI-based tools developed in-house, to optimise your processes and products.

- Developing alternative propulsion systems, alternative fuel systems, and emission measurements of internal combustion engines.

- Vehicle data analyses using simulations and reverse engineering on CAN bus systems.

Contact us without obligation

- Call +32 3 502 22 16

- E-mail jeroen.geuens@kdg.be

Karel de Grote Hogeschool

Karel de Grote Hogeschool