- We developed a software tool for replacing traditional solvents in existing industrial applications with eco-friendly alternatives.

- Goal:

- Greening chemical processes.

- Target group are SMEs because there are fewer resources for R&D there.

- Low-threshold tool, which can also be used by people without a strong chemical background.

- Read the blog

- Follow-up study: Greener solvents for conservation

Contact

jeroen.geuens@kdg.be

+32 3 613 19 24

-

Duration of study: 1 October 2015 - 30 September 2017

-

Research centre: Sustainable Industries

-

Project partners:

-

Caldic Belgium NV

-

Boss Paints NV

-

Ecover NV

-

Proviron Industries NV

-

Eco-point BV

-

QFrame

-

Sustainable solvent selection using AI

The need for a systematic approach

Solvents are frequently used as diluents in chemical production processes and products like paint, cleaning agents, glue and ink. Most classical solvents are non-renewable, non-biodegradable, flammable or toxic. More sustainable alternatives are available but the search for the best solution is often time consuming and labour intensive. Moreover, chemists typically first draw up a list of potential solvents based on their own limited knowledge ( “What did I use in the past?”) and from a pragmatic point of view (“What do we have in stock?”) and then make a choice based on (unsystematic) trial and error.

To enable a more efficient, objective and purposeful selection of solvents, researchers of the Karel de Grote University College (KdG) have developed a user-friendly software tool based on an AI algorithm, called SUSSOL (Sustainable Solvents Selection and Substitution Software), through a partnership between the Centre of Expertise on Sustainable Chemistry and Applied Sciences.

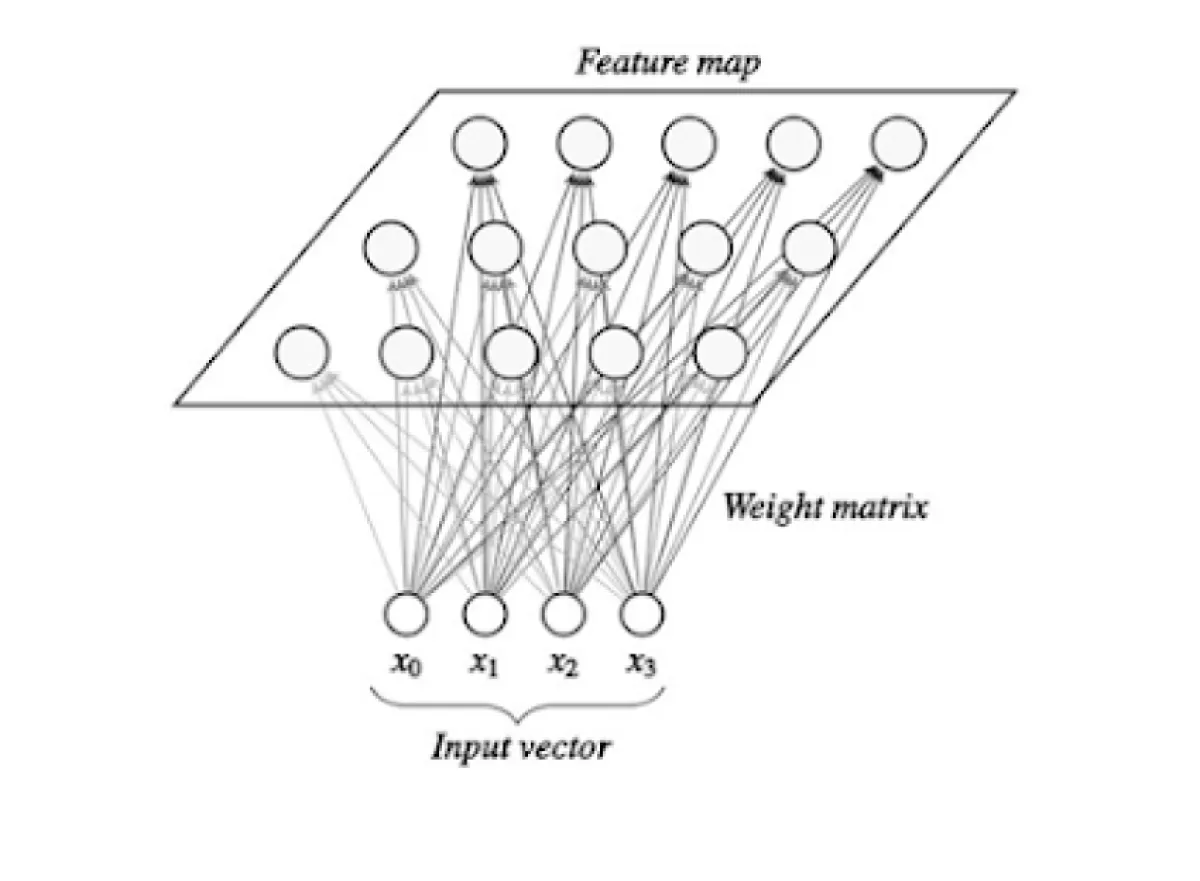

SOM - Self Organising Map

The first results

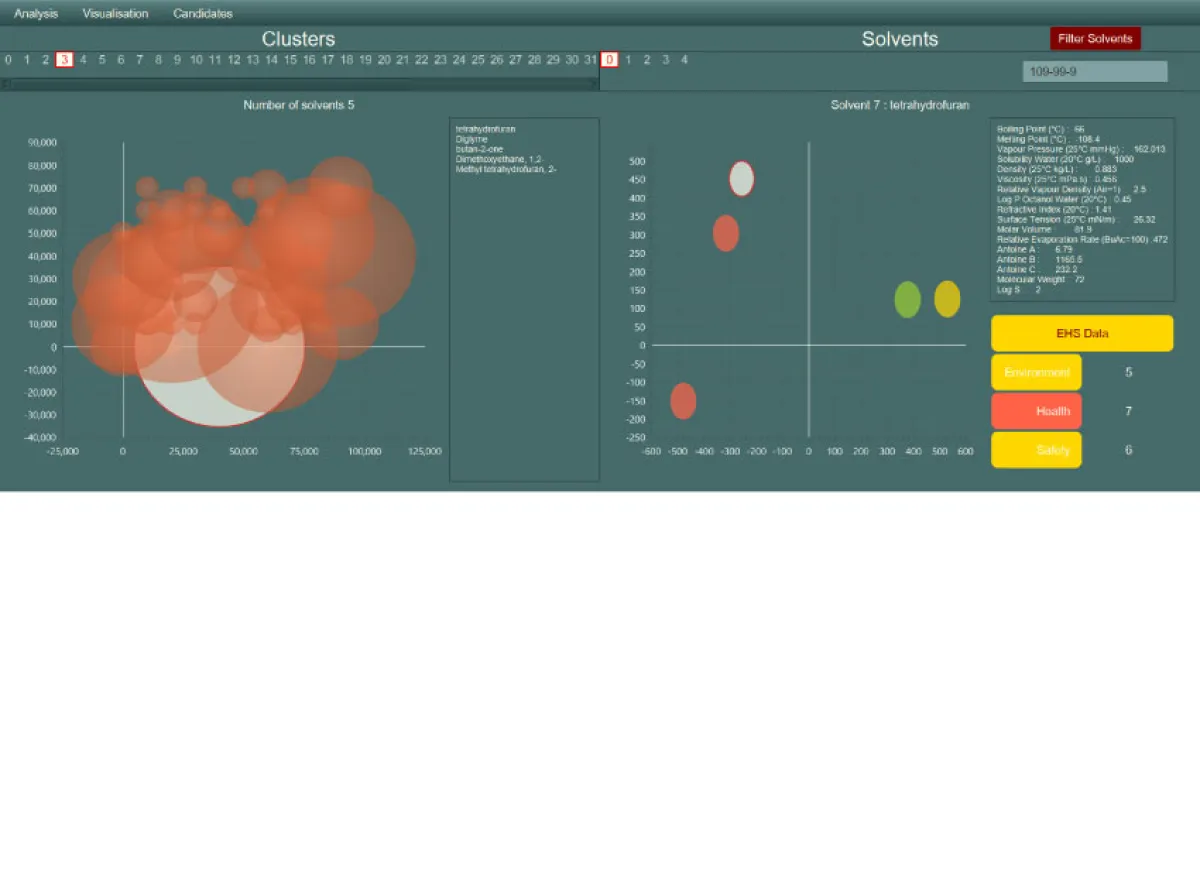

After three years of intensive development, tests and statistical validation, the software is ready for use. And the first results are promising: SUSSOL has already successfully been used for determining suitable alternative solvents for white spirit in paint, liquid-liquid extractions and a chromatographic application. The software tool is currently being used by Soudal, Eco-Point, Janssen Pharmaceutica and MCU Coatings to identify sustainable solvents (sometimes as part of a mixture) that meet their specific requests, either for substitution in existing or for use in new applications. Based on the desired solvent properties the software tool generates a shortlist from which the users then select, in consultation with the KdG researchers, the most interesting solvents for lab tests.

Trusted us

How it works

Clustering using Neural Networks

A solvent dataset is fed to the AI algorithm (a Self-Organizing Map). We can create a subset based on our 553 solvent set, or use the clients own dataset. The algorithm clusters the solvents with similar physical properties and characteristics. We perform 1000 runs on the dataset and determine which solvents are statistical significant neighbors. A shortlist is created and ranked automatically along the HS&E parameters so that you immediately see the HS&E impact of every alternative. For a more in depth explanation, read our publication in the Molecules special issue on Bio-Based and Safer Solvents.

553 solvents and 22 parameters

Our database contains 553 solvents and 22 parameters, many of those are not included in other solvent selection software or databases, such as surface tension, refractive index, density, viscosity, flashpoint, autoingition temperature, … The database only includes experimental data.

Sustainable Solvents

Our database contains the ‘Green Solvents’, but also includes common organic solvents. The list of 'green alternatives' is rather small but often it is possible to find a solvent that is healthier, or safer, without being green in all aspects.

A Neural Network to Cluster Solvents

The Artificial Intelligence module is a Neural Network. We applied the ‘Self-Organising Map’ or SOM of Kohonen, a Finnish AI researcher. Based on the physical properties only (numerical data solely) similar solvents are clustered. Link to the article here.

The SOM is based on how our visual brains perceive lines and how they categorise these lines. All the properties of the solvents are coded in a list (a vector). These vectors are offered to the network, a kind of cerebral cortex one could say. These vectors are firstly placed in a random order, but via a certain logic, similar vectors become neigbors. And this learning process comes to an end when the vector stop moving. The system then converges to an equilibrium (homeostasis) and it stops learning.

The process described above is performed 250 till 1000 times, that is what we call clusterings. The results of each clustering (the map) is stored. And then finally we perform a statistical analysis to determine which are the best clusterings. We then analyze the clusters of the 100 best performing clusterings and we look for the most frequent neighbor of each solvent.

An extra advantage of the neural network is that it learns. When new solvents are added in the database, then then knowledge model becomes smarter, it makes new connections, which is not possible with a static database.

The added value of AI in the selection process

The challenge is to find a row with similar values in the database which is a matrix of 12.166 numbers. This is, if done manually, a painstaking proces of searching and comparing numbers.

In a complex and noninterpretable database the AI algorithm provides structure and chemical significance by distributing solvents in groups with similar properties.

Moreover several chemists experienced that it remains so far unclear what exact property is responsible for the desired action or reaction in a specific application, which makes you look for a needle in a haystack in the event you consider to browse through the solvents space manually.

Researchers

Want to know more, collaborate or have a press question?

You can collaborate with our research centre Sustainable Industries on topics such as:

- Greening chemical processes and reusing waste streams.

- AI-based tools developed in-house, to optimise your processes and products.

- Developing alternative propulsion systems, alternative fuel systems, and emission measurements of internal combustion engines.

- Vehicle data analyses using simulations and reverse engineering on CAN bus systems.

Contact us without obligation

- Call +32 3 502 22 16

- E-mail jeroen.geuens@kdg.be

Karel de Grote Hogeschool

Karel de Grote Hogeschool